|

The Workplace

(Heath, Safety and Welfare) Regulations 1992

Why

bother about glazing?

Since 1975 the Health and Safety at Work etc Act 1974 (HSWA) has required

employers,the self employed and certain people who have control over

workplaces to ensure, so far asis reasonably practicable, the health

and safety of anyone who may be affected by their work activities. So

if glazing constitutes a risk, reasonably practicable measures need

to be taken todeal with it.

The HSWA does not specifically mention glazing, but on 1 January 1993

the Workplace (Health, Safety and Welfare) Regulations 1992 came into

force to implement the EC Workplace Directive. Regulation 14 includes

requirements for glazing which make explicit those that are implicit

in the HSWA. The regulations apply to a wide range of workplaces including

factories, offices, shops, schools, hospitals, hotels and places of

entertainment. They do not apply to domestic premises used for work,

or to construction sites. They have applied to new workplaces from 1

January 1993 and they will apply to all workplaces from 1 January 1996.

The duty to comply with the regulations will usually fall to the employer.

However, people other than employers may be duty holders under the regulations

if they have control of a workplace to

any extent; such as owners and landlords of buildings used as workplaces.

Depending upon the tenancy agreement, particularly of a multi-occupied

building, the owner, as opposed to individual employers, may be the

duty holder responsible for complying with the requirements.

back

to top

What

Regulation 14 requires

The Regulation requires that every window or other transparent or translucent

surface in a wall, partition, door or gate should, where necessary for

reasons of health or safety, be of a safety material or be protected

against breakage of the transparent or translucent material; and be

appropriately marked or incorporate features to make it apparent.

back

to top

What

the duty holder needs to do

The regulation only expects action "where necessary for reasons

of health or safety". So you need to assess every window or other

transparent or translucent surface in a wall, partition, or door or

gate to establish whether there is a risk of anyone being hurt if people

or objects come into contact with it, or if it breaks.

back

to top

If

there is no risk, no further action is required. If there is a risk

then action will be necessary to comply with the regulation to:

· prevent people

or objects coming into contact with the glazing, or

· upgrade it so that if it breaks, it breaks safely, and

· mark large expanses of glazing in some way so that people know

it is there.

.back

to top

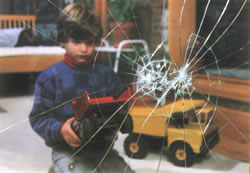

Assessing

the risk

The assessment needs to take into account all relevant factors such

as the location of the glazing, the activities taking place nearby,

the volume of traffic and pedestrians, and any previous experience of

incidents. Glazing in some locations may be a higher risk, such as:

· in doors and gates, and door and gate side panels;

· where any part of the transparent or translucent surface is

at shoulder level or below;

· in windows, walls and partitions, where any part of the transparent

or translucent surface is at waist

· level or below.

back

to top

Taking

action

What needs to be done will depend on the extent of the risk in individual

circumstances. You may need to:

· reorganise traffic routes (either for people or vehicles) to

avoid the risk of glazing being broken;

· put up suitable barriers or screens to prevent people or vehicles

coming into contact with the glazing.

· The size or strength of the barrier or screen will depend on

who, or what, needs to be kept away from the glazing;

· modify the glazing to reduce the risk of injury eg, by applying

a safety film which prevents it shattering

· in a dangerous manner, or by marking it to prevent people bumping

into it;

· limit the area of glazing;

· replace the glazing with a safety material.

back

to top

Safety

materials

Some examples of safety

materials are:

· materials which are inherently robust such as polycarbonates

or glass blocks; or

· glass which if it breaks, breaks safely, ie glass which breaks

in a way that does not result

· in large sharp pieces; or

· ordinary annealed glass which meets the following thickness

criteria:

Nominal thickness Maximum size

8 mm 1.1 m x 1.1 m

10 mm 2.25 m x 2.25 m

12 mm 3 m x 4.5 m

15 mm Any size

back

to top |

|